Message

LUCHS IV Register Measuring System Improved with Varnish Register Capabilities

In December 2016, the Bundesverband Druck und Medien e. V. (The German Printing and Media Industries Federation) published the guideline "Technical Acceptance Test of Coating Units on Sheetfed Offset Printing Presses". It was developed in cooperation with printing press manufacturers, the technical consultants of the regional printing associations and the Sächsisches Institut für die Druckindustrie and define the exact conditions and target values for this quality inspection. The printing substrate, printing speed, and climate conditions are standardized so that results can be comparable. Depending on the printing press format, up to 16 measuring elements are arranged at regular intervals across the sheet. The sheets of the glossy-coated printing paper to be used for the test are varnished at 85% of the maximum press speed. The gloss values of each position are then determined on 10 randomly selected sheets from a press run of 100 sheets. The homogeneity and consistency of the applied varnish are examined.

Research Project at the Institute

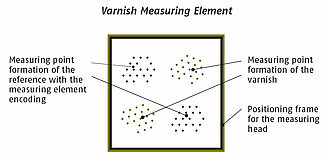

As part of this development, a research project was carried out at the Sächsisches Institut für die Druckindustrie in Leipzig. The aim was to find a way of determining the position of the varnish applied in the press in a manner comparable to the well-known register measurement of visible inks. Determining the position of transparent or barely visible varnishes and inks that are to be only partially applied has until now been an unsolved technical challenge. This is an important and necessary process given the increasing number of jobs with varnish enhancements, especially since there is also a trend towards spot varnishes. Here, the correct position of the varnish application in relation to the "visible" inks is of crucial importance.

Expansion of the LUCHS IV with Varnish Register Capabilities

The LUCHS IV Register Measuring System from PITSID GmbH has been used worldwide for many years for measuring the registration in printing presses. This 4th generation system has now been improved by the "varnish registration" function for determining the position of the varnish in relation to the printed image.

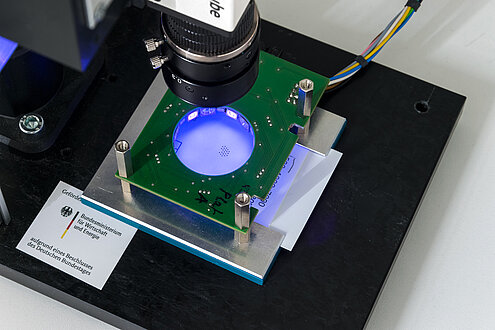

Additional Light Source

An additional light source is needed in the measuring head for measuring the varnish register. Both types of measuring elements can then be made visible to the system with one measuring head. Depending on the measurement mode, the corresponding illumination unit is switched on. In this way, only the measuring elements specifically provided for the varnish register measurement are evaluated. The corresponding display is shown in the same way as the colour register measurement and the fluctuation of the varnish position is displayed in relation to the reference colour.

Reliable Verification of Varnish Application Accuracy

With the additional functionality described above, which has now been integrated into the 4th generation of the LUCHS Register Measuring System, the foundation has been laid for verifying print enhancement processes at press manufacturers and end-users. Whereas its use was previously "limited" to printing units, coating units can now also be easily checked for accuracy.

For this reason, the range of services offered by the accredited Test Laboratory for Printing Quality and Post Press of the Sächsisches Institut für die Druckindustrie has been extended to include the acceptance test of coating units either as part of press acceptance tests or on an individual basis. PITSID GmbH and the Sächsisches Institut für die Druckindustrie can be contacted for questions regarding the use and application possibilities of the system as well as questions regarding the various acceptance test procedures.